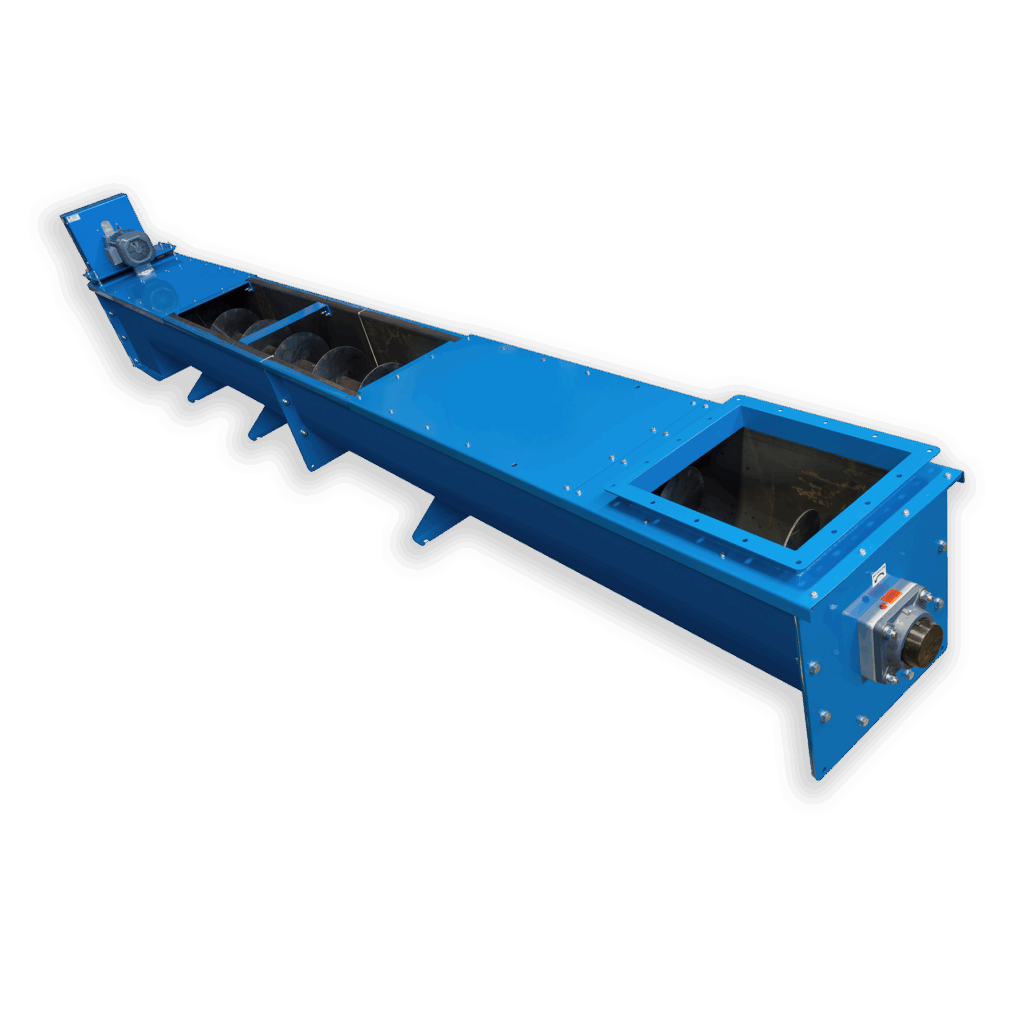

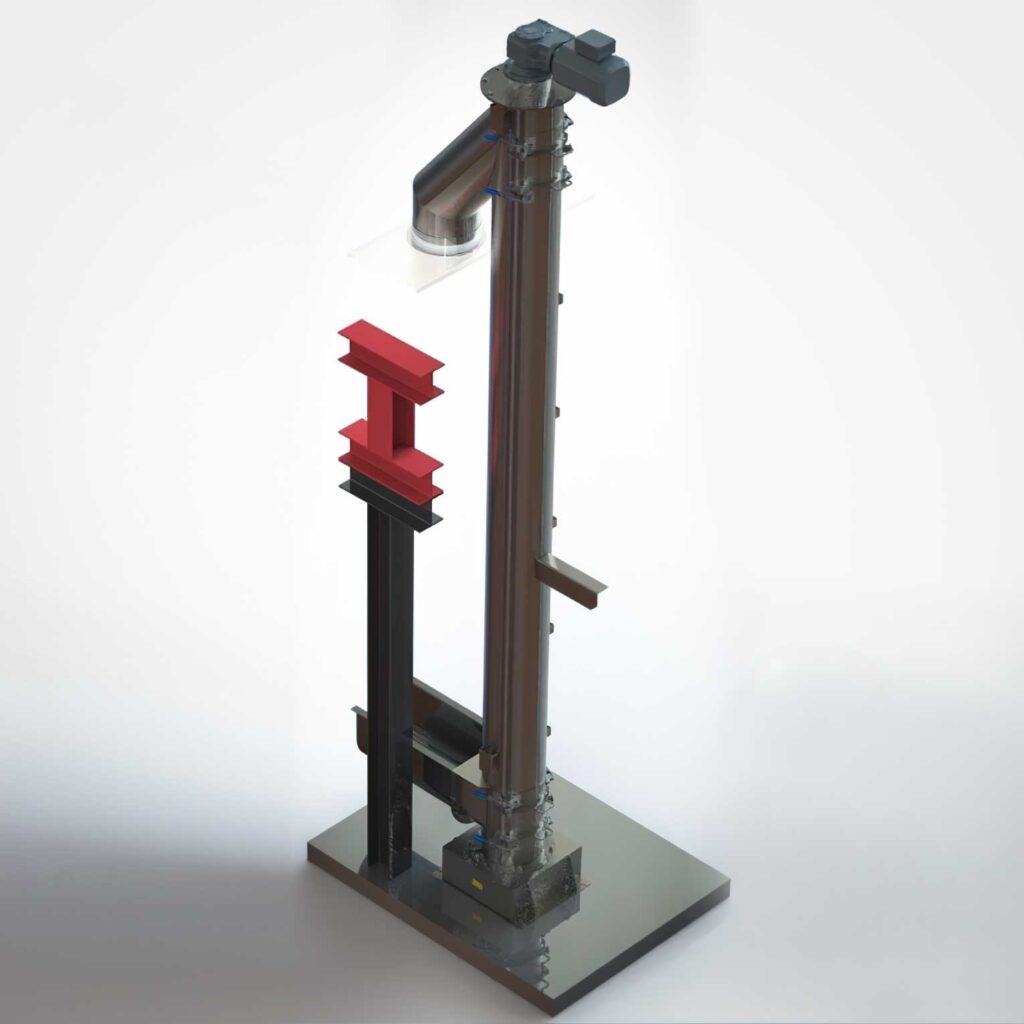

Screw conveyors are used in many different industries. We can create custom designs, with a variety of different features, to accommodate any particular requirement.

Advantages include the following:

- Screw conveyors are capable of handling a wide variety of bulk materials from sluggish to free-flowing,

- They are flexible, can have multiple inlet and discharge points, allowing bulk materials to be conveyed and distributed to multiple locations. Slide gates or valves can be added to control the flow into and out of a screw conveyor,

- They can be used as a metering device to take product from a hopper or bin into the process stream,

- They are compact and adaptable to congested locations,

- They are totally enclosed to prevent spillage,

- They can be used in the horizontal, vertical, or any inclined position to suit the product being handled,

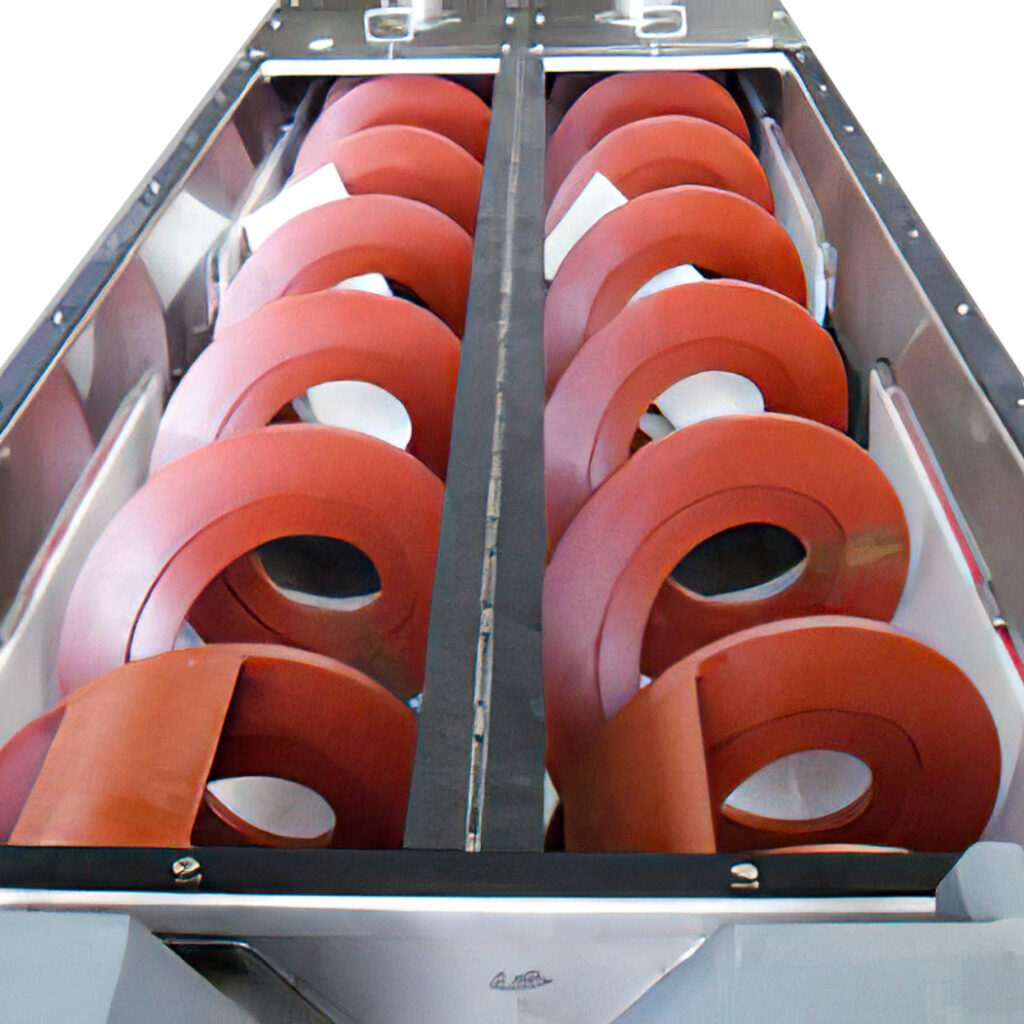

- They can be designed without a centre pipe. This is called a shaftless or centreless screw conveyor and is designed for conveying wet, sticky, or sluggish products,

- They can be used for mixing various products together or as a de-lumper on products,

- They can be jacketed, or have a hollow-flight design used to provide the necessary heat transfer or cooling required for products,

- They can provide an air lock in the process stream,

- They can be manufactured in a variety of materials to suit your particular requirements – mild steel, stainless steel, or abrasion resistant material,

- They can be designed for easy cleaning. They can incorporate quick removable covers, drop-bottom casings, and internal spray systems – all to your particular application.